Vertical PP Acid Fume Hood Scrubber for Waste Gas Treatment

Model:JH-FSP003

Description of PP Fume Hood Scrubber

This acid-base waste acid fume hood scrubber for waste air treatment is made of PP material, and there are no metal components inside the system. Therefore, the entire system has extremely high resistance to strong acidity and alkalinity.

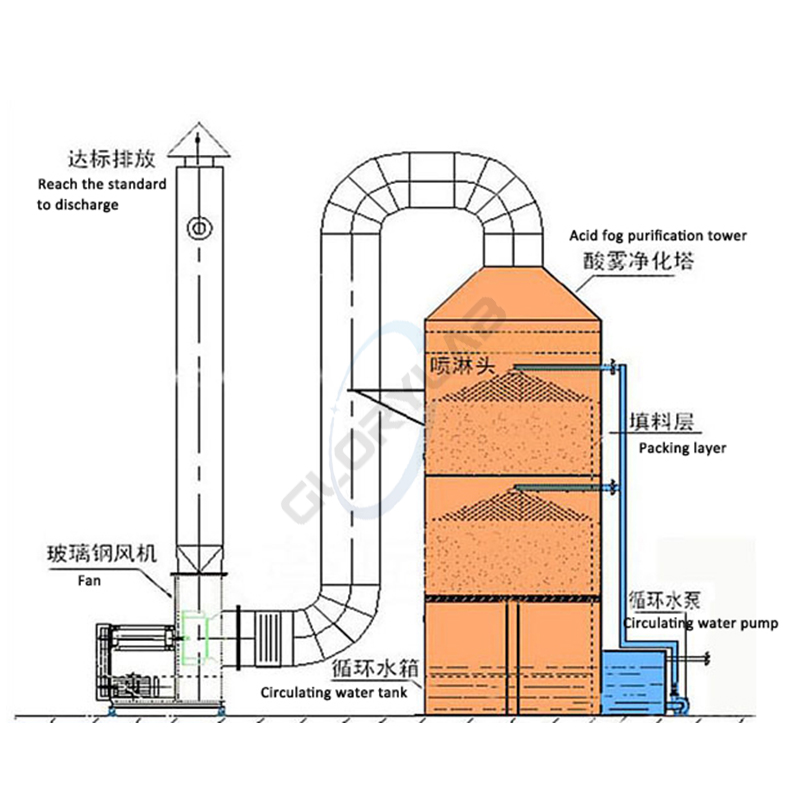

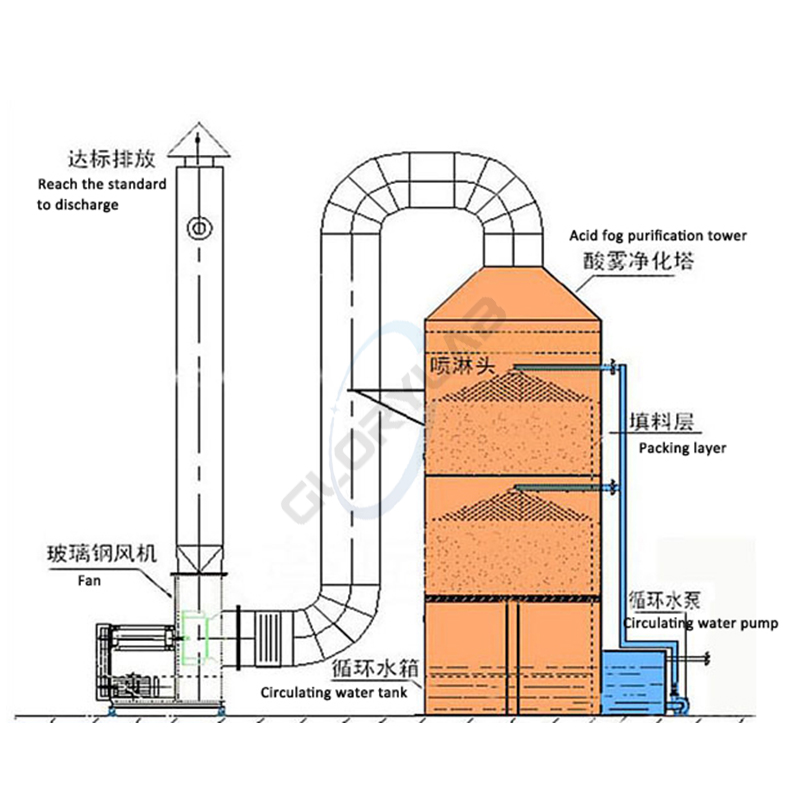

1. Equipment composition: The equipment adopts a vertical cylindrical design and is equipped with a gas-liquid reaction chamber, a reverse packing absorption system, a spray system, a dehazing device system, a liquid circulation supply system, and an automatic dosing system (optional). It is also equipped with a supply system water tank, water supply pump system, peripheral windows, and air inlet and outlet ports.

2. The filtering filling layer adopts PP annular packing. The porosity of the packing material is above 0.85, which not only provides a large contact area between the gas-liquid phase on the packing medium, but also ensures its good gas passing performance.

3. The defogging layer uses high-efficiency defogging plastic mesh as the defogging agent, and its water vapor removal rate can reach over 90%.

4. The circulating water pipe and the drainage pipe are both independent operating systems. The circulating water pipe of fume hood scrubber is made of PP material, and the drainage pipe is made of PVC material. The drainage pipe is designed as an integral part of the anti overflow outlet; The nozzle of the water spraying system is a high-pressure spiral spray nozzle, which is not easy to block, has a large spraying angle, and has uniform distribution of droplets.

5. The circulating water tank and acid fume scrubber adopt an integrated design, with water inlet, overflow prevention outlet, and drainage outlet, and an automatic water stop device is installed at the water inlet.

6. The window adopts a circular design for observing the operation and maintenance of the equipment.

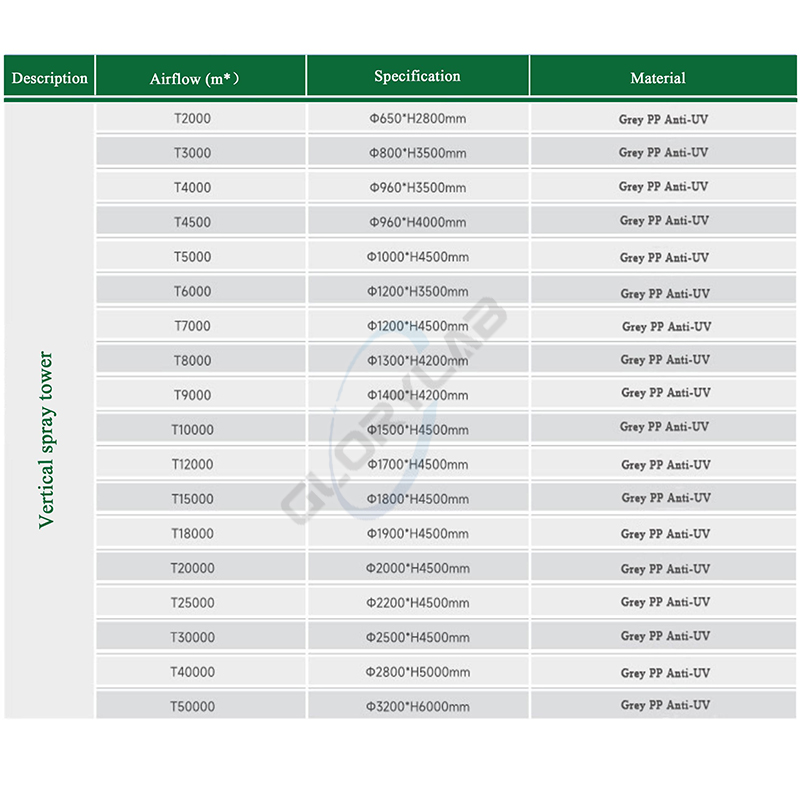

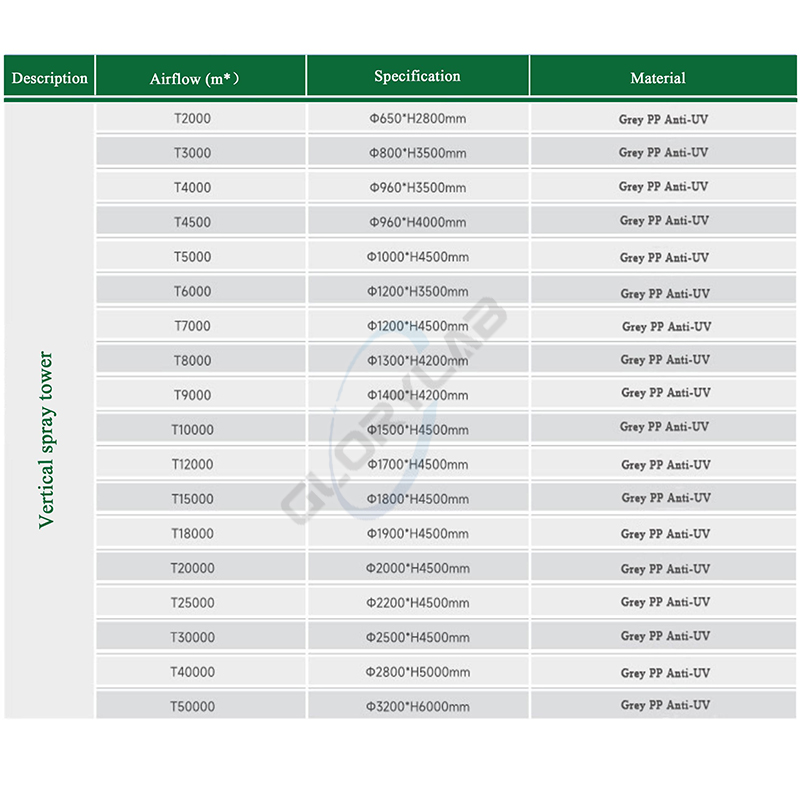

Product Specification

How to Operate Acid Chemical Fume Scrubber?

1. Fill the water level of the water tank and distribution tank to the overflow of the equipment and open the water inlet valve.

2. Check the pump and fan and tighten all connection bolts in time.

3. Fill the spray tank on the PP fume hood scrubber with water.

4. Add 15kg sodium hydroxide and stir the solution to dissolve.

5. Check the fan, spray pump and other parts, and restart the powder switch button.

The use of PP chemical acid fume scrubber for fume hood should follow a certain process, and the daily operation can be followed to avoid other failures in the process of use and prolong the service life of the equipment.

Product Advantage

1. High-tech packing technology to ensure purification efficiency.

2. The resistance loss is small, the specificsurface areais large, the chemical reaclion is perfect and the speed is fast,

3. Reasonable product design, corrosion resistance andaging resistance, high absorplion and purification rate, the neutralization andremoval effect of 95% white dynamicdosing device. Low operating cost and easy maintenance.

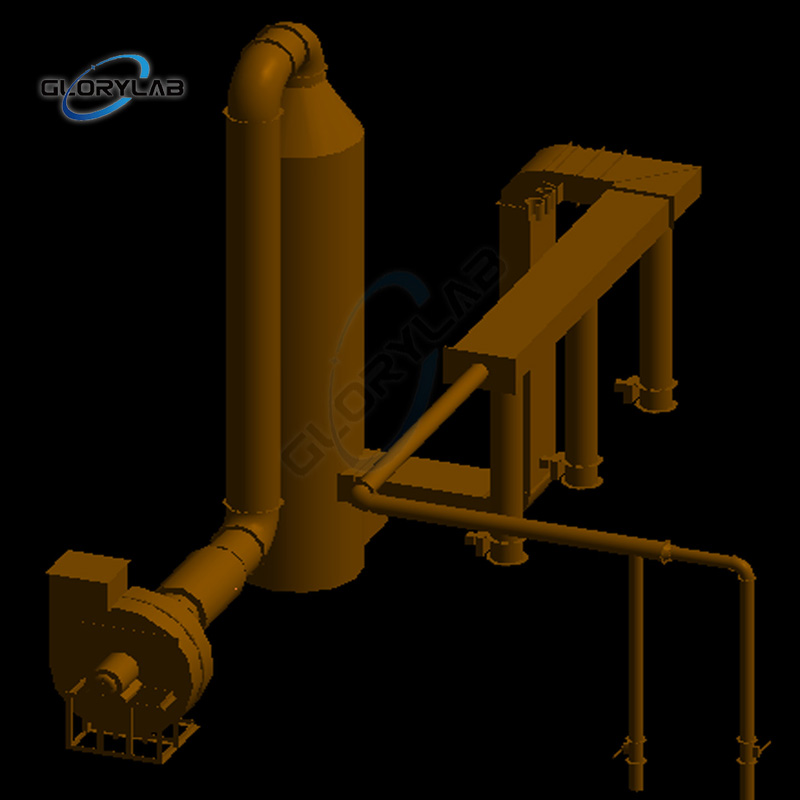

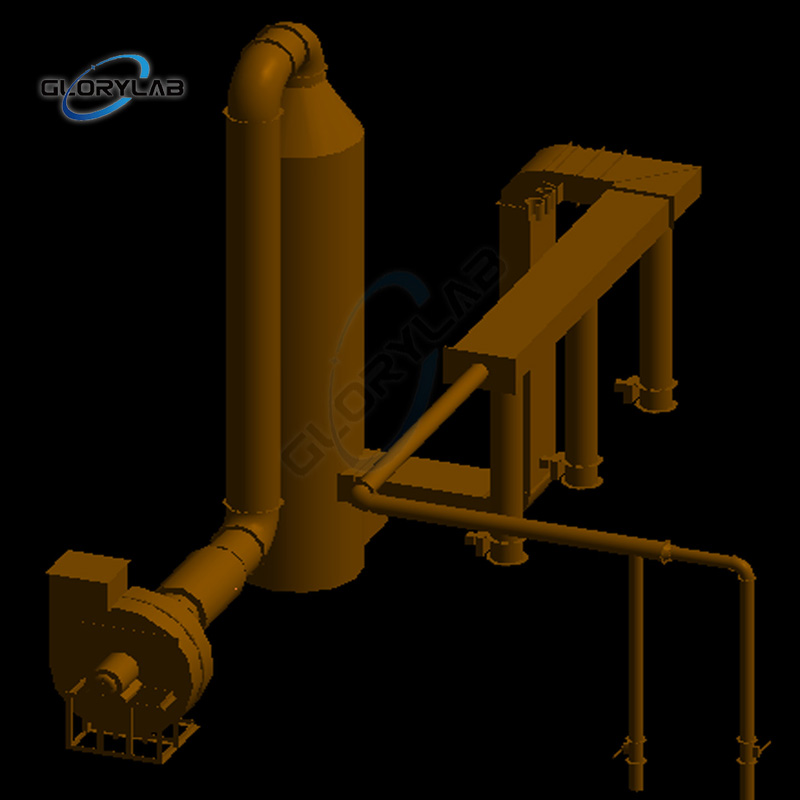

Design Sample of Fume Scrubber for Fume Hood

Ventilation System with Fume Scrubber and Fume Hood

Delivery Picture

Drawing of Fume Scrubber