Developping Trend for Laboratory Fume Hood

2024-08-09

The development trend of laboratory fume hood mainly includes safety, intelligence,greenness,customization,energy saving performance etc.

Safety performance of laboratory fume hood

Safety performance is the most critical performance for any type of laboratory fume cupboard. Safety means that laboratory staffs can maintain healthy in harsh chemical working environment.

For normal fume hood on the market,there is not any safety standards which leads to heavy leakage rate during experiments. The harm is serious from various chemicals to lab staffs especially who have worked in laboratory for long time.

With introducing foreign fume cupboard standard such as ASHRAE110 and EN14175 standard, we gradually apply these testing standards into actual designing, production and testing procedures. Glorylab rolled out ASHRAE110 fume hood completely complying with ASHRAE110 standard tested by authorized SGS inspection center.We are proud to declare that our fume hood is safe enough because its leakage rate is only 0.00ppm at normal face velocity 0.5m/s.

Intelligence and automation of lab fume hood

With the advancement of technology and the increasing demand for laboratories, lab fume hood industry is undergoing rapid development and transformation. The trend of intelligence and automation enables fume hoods to achieve more precise and efficient ventilation control by introducing advanced sensors,control systems,and data processing technologies, reducing the frequency of manual intervention and improving system stability and reliability.

Fume hood greenness and customization

Energy saving and greenness are the two major trends in the development of laboratory fume hoods.

To reduce energy consumption and environmental impact,the new ventilation system will adopt more efficient air filtration technology and environmentally friendly materials

In addition, customization has become an important development direction to meet the specific needs of different laboratories.

Energy saving performance of fume cupboard

This function can realize by optimizing the design of laboratory fume hood, increasing its efficiency, optimizing the laboratory air circulation system, adopting a ductless clean air type fume hood, and applying a variable air volume control system (VAV).We will tell details in following articles.

Glorylab will devote to build a healthier, safer, and more comfortable experimental environment for each lab staff by following above mentioned trends and take action to practice in normal work.

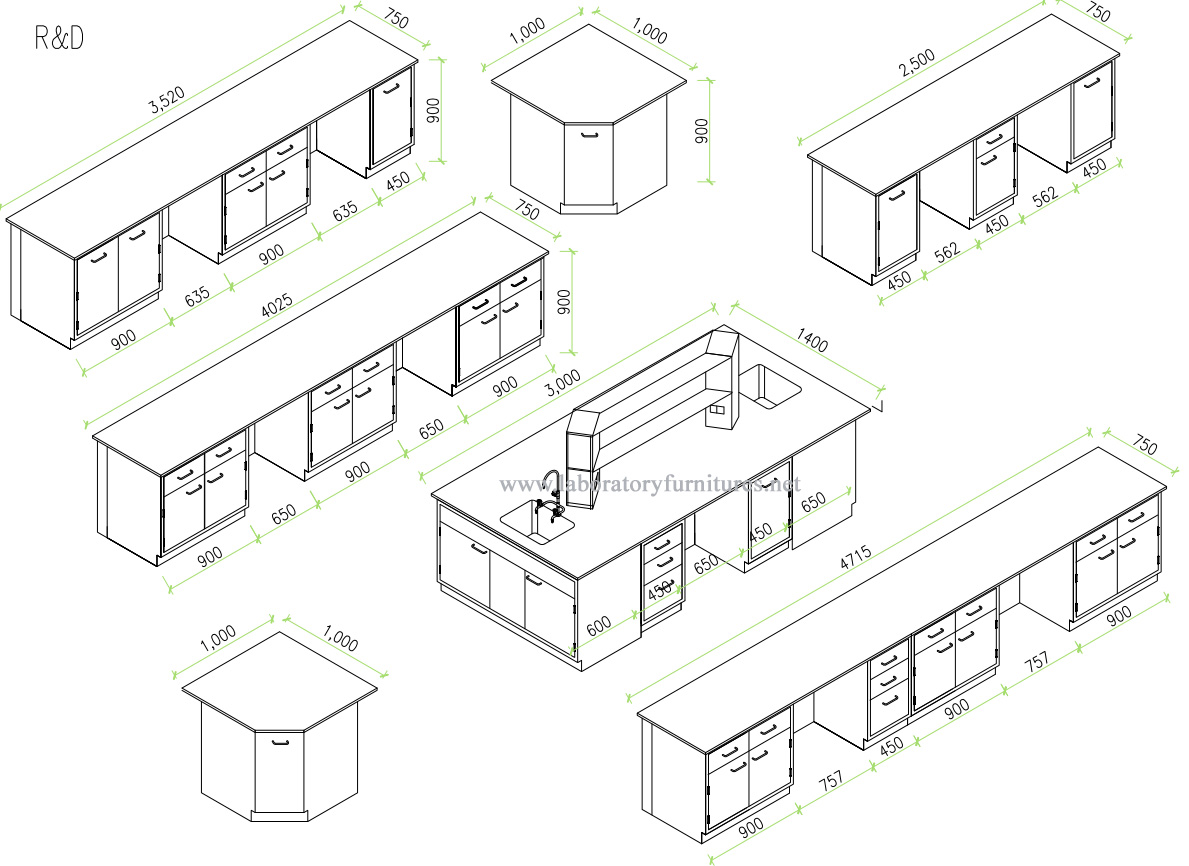

Sample of 2D drawing:

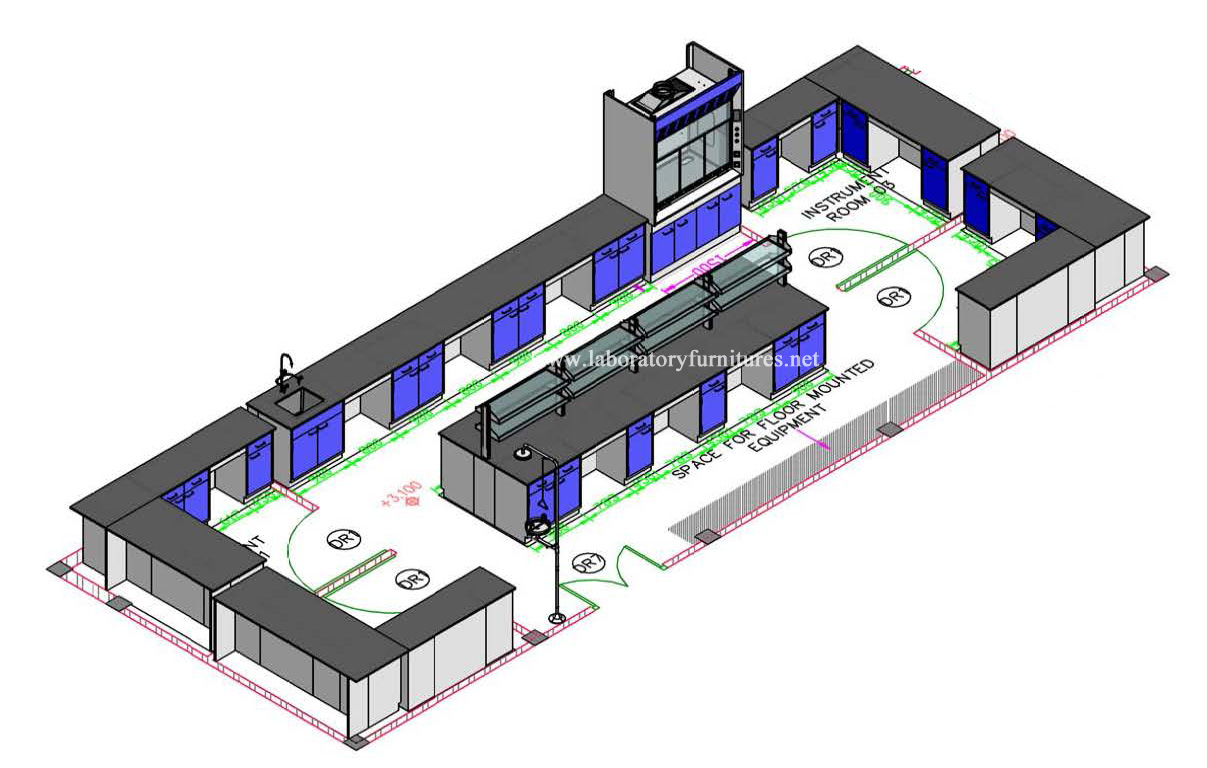

Sample of 3D drawing: